- Introduction expand_more

- Performance expand_more

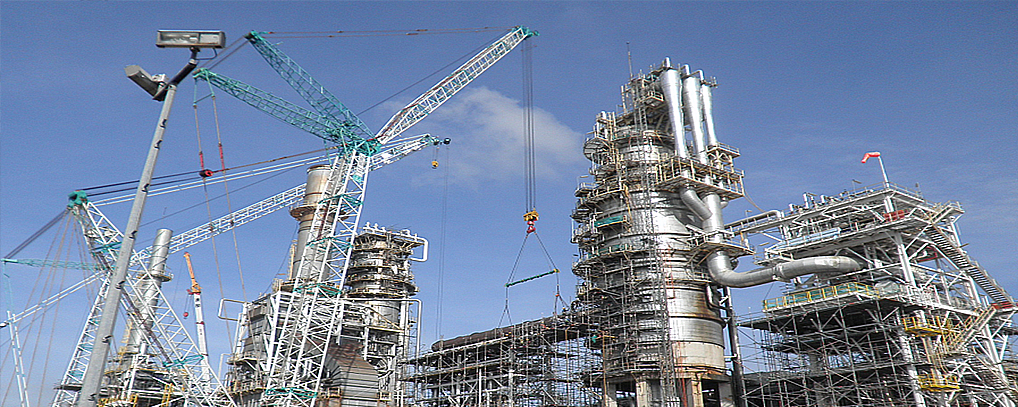

Works for facility improvement are to modify or replace the components of existing facilities and to

enhance their capacities and performance and in need of optimal manpower and construction period within the shortest possible timeframe.

(Facility improvement works aim to increase capacity and enhance performance through the modification and replacement

of components in existing facilities, utilizing optimal manpower and construction equipment within the shortest possible timeframe.)

Our company has extensive experience in performing numerous facility improvement projects for the main components,

including Reactor, Regenerator and Cracking Furnace/Heater, of FCCUs, RFCCUs, VDUs, CDUs, and NCCs in both domestic

and international petroleum and petrochemical refining plants.

As for our major projects, there were the Fluid Catalytic Cracking Unit (FCCU) at Reliance in India in 2005 and

the Vacuum Distillation Unit (VDU) at Petronas in Malaysia in 2010. Subsequent projects linked to these include the

Crude Distillation Unit (CDU) at Sonatrach in Algeria in 2011, the Crude & Aromatic Distillation Unit at Sonatrach in 2013,

the Naphtha Cracking Center (NCC) by Samsung/Hanwha Total in 2015,

and the Residue Fluid Catalytic Cracking Unit (RFCCU) at S-Oil in 2016.

In addition,

we have been carrying out facility improvement work on auxiliary equipment for power plants,

and for our main project, there was the expansion project for H.P Heater equipment to increase turbine capacity

of the Gunjang Combined Heat and Power Plant in 2011.

With our rich experience and expertise in improvement projects, we will focus on taking the quality of improvement and

maintenance of power generation facilities to the next level.

| NO | Place | OWNER | Work Description for Revamping | Main Material | Scope of Work | Period |

|---|---|---|---|---|---|---|

| 1 | Yeosu, Korea | YNCC | Modification / H/EX Shell Replacement- BD G- EA102 / 701 Shell & T/ Bundle With Piping,Valve,Filter & Strainer | A516-70 | Design, Fabrication & Modification for H/EX Shell / Piping & Valve | 2018-05 2018-04 |

| 2 | Yeosu, Korea | YNCC | Modification / Ethylene - C/HTR BA-101RADIANT COIL Fabrication & Modification for Heater Coil, USX Cone & Y-fitting | HTE, INCONEL,SUS 304H | Design, Fabrication & Modification for Heater Coil, USX Cone & Y-fitting | 2018-01 2018-04 |

| 3 | Yeosu, Korea | Hanwha Total | G1-DC520, REACTOR Modification Design, Fabrication & Modification for REACTOR Modification | A516-70/A106/SUS | Design, Fabrication & Modification for REACTOR Modification | 2017-09 2018-03 |

| 4 | India | Reliance | Reliance FCCU Modification (Reacto &, Regenerator with catalyst line) | SA387-22-1 / SA516-70 | Design, Fabrication & Modification for Equipment,Piping, Structure & Others | 2017-02 2017-12 |

| 5 | Yeosu, Korea | YNCC | Modification / Heat exchange - E-EA443A/C, #2 T-555B SHELL & T/ BUNDLE With Piping,Valve,Filter & Strainer / CHP Mist Eliminator | SUS304H, A192 | Design, Fabrication & Modification for SHELL& T/BUNDLE With Piping, Valve, Filter &Strainer / CHP Mist Eliminator | 2017-02 2017-06 |

| 6 | Yeosu, Korea | YNCC | Heat exchange - Design, Fabrication & Modification for H/EX Bundle / Column With Piping,Valve,Filter & Strainer | SUS304H | Design, Fabrication & Modification for H/EX Bundle / Column With Piping, Valve, Filter & Strainer | 2016-01 2016-06 |

| 7 | Yeosu, Korea | YNCC | Design, Fabrication & Modification for Heater Coil, USX Cone & Y-fitting of BA-105 / F-160 | INCONEL(KHR45) SUS304H | Design, Fabrication & Modification for Heater Coil, USX Cone & Y-fitting of BA-105 / F-160 | 2016-01 2016-02 |

| 8 | Yeosu, Korea | YNCC | Modification / Design, Fabrication & Modification for Heater Coil, USX Cone & Y-fitting | INCONEL(KHR45) SUS304H | Design, Fabrication & Modification for Heater Coil, USX Cone & Y-fitting | 2016-01 2016-04 |

| 9 | Yeosu, Korea | YNCC | Design, Fabrication & Modification for H/EX Shell & Bundle With Piping, Valve,Filter & Strainer (T-310 A/B, T-203) | A516-70 | Design, Fabrication & Modification for H/EX Shell & Bundle With Piping, Valve, Filter & Strainer | 2016-01 2016-05 |

| 10 | Onsan, Korea | S-OIL | Revamping (Up grading 73MBD → 75MBD ) Modification for RFCC Unit (Package 1) & PKG-2 MHC Revamping | A516-70/A106/SUS | Design, Fabrication & Modification for RFCC Unit & PKG-2 MHC Column / Separator | 2015-06 2016-10 |

| 11 | Deasan, Korea | STC | STC NCC Heater - Modification of existing 4 set of Radiant Coil Revamping with Piping | SA516-70/ SA335 | Design, Fabrication & Modification for Heater Coil | 2015.05 2015-08 |

| 12 | Yeosu, Korea | YNCC | YNCC #2 CRACKING HEATER (F-110) - Design, Fabrication & Modification for Heater Coil, USX Cone & Y-fitting | INCONEL(KHR45) SUS304H | Design, Fabrication & Modification for Heater Coil, USX Cone & Y-fitting | 2014-01 2014-04 |

| 13 | Deasan, Korea | STC | STC NCC Heater - Modification of existing 3 set of Radiant Coil Revamping with Piping | SA516-70/ SA335 | Design, Fabrication & Modification for Heater Coil | 2013-11 2014-04 |

| 14 | Yeosu, Korea | YNCC | REVAMPING WORK FOR #2 AROMATIC AREA PIPING / STORAGE TANK | SA516-70/ SA335 | Design, Fabrication, Modification & Replacement OF Tank Shell, Bottom, Piping & Valves, ETC. | 2013-10 2014-01 |

| 15 | Yeosu, Korea | YNCC | Modification of C/HTR F-180 RADIANT COIL (Convection casing part) | INCONEL(KHR45) SUS304H | Design, Fabrication & Modification for Heater Coil | 2013-05 2013-06 |

| 16 | Onsan, Korea | S-OIL | Modification for R2R (RFCC) Cooler Stand Line | SA387-22-1 | Engineering for Modification | 2012-03 2013-12 |

| 17 | Algeria | Sonatrach | Revamping (Up grading 30 KBPSD → 39 KBPSD ) for Crude Distillation Unit (2 Unit) of Sonatrach Akida Refinery Demolition, Erection & Modification for Equipment (Heater, Column, Vessel, Heat-Exchanger, Air fin Cooler & Others), Piping, Structure & Others | A516-70/A106/SUS | Demolition, Erection & Modification for Equipment (Heater, Column, Vessel, Heat- Exchanger, Air fin Cooler & Others), Piping, Structure & Others | 2011-04 2012-05 |

| 18 | India | Reliance | Revamping (Reliance Jamnager Refinery)- Regerator & Reactor with Catalyst Line for FCC Unit | SA387-22-1 / SA516-70 | Design, Fabrication & Modification for Equipment, Piping, Structure & Others | 2010-09 2011-12 |

| 19 | Algeria | Sonatrach | Revamping (Up grading 15 KBPSD → 20 KBPSD ) for Crude Distillation Unit of Sonatrach Arzew Refinery | A516-70/A106/SUS | Demolition, Erection & Modification for Equipment(Heater, Column, Flare Stack, Gasturbine/Generator & Others) | 2010-08 2011-10 |

| 20 | Malaysia | Petronas | Revamping (Up grading 20 KBPSD → 30 KBPSD ) for Vacuum Distillation Unit of Petronas Malaysia Refinery | A516-70 | Demolition, Erection & Modification for Equipment, Piping, Structure & Others | 2009-11 2010-02 |

| 21 | India | Reliance | Reliance FCCU Modification (RG /Transfer line) of Reliance Jamnager Refinery | SA387-22-1 | Design, Fabrication, Modification & Modification for Equipment, Piping, Structure & Others | 2010-11 2011-03 |

| 22 | Yeosu, Korea | Hanwha Chemical | LDP Bulk Loading System -Design, Fabrication & Modification for Equipment, Piping, Structure & Others | SA516-70/ SA335 | Design, Fabrication & Modification for Equipment, Piping, Structure & Others | 2007-11 2008-02 |

| 23 | Yeosu, Korea | YNCC | YNCC No.1 Revamp Project / Superheater Demolition Work | 5 Cr-1/2 Mo, SA387-22-1, SA516-70 | Design, Fabrication & Modification for Equipment, Piping, Structure & Others | 2006-08 2006-12 |

| 24 | India | Reliance | Revamping (Up grading 130 KBPSD →200 KBPSD ) for FCC Unit of Reliance Jamnager Refinery | SA387-22-1 | Design, Fabrication & Modification for Equipment, Piping, Structure & Others | 2005-09 2005-11 |

| 25 | India | Reliance | Revamping (Up grading 130 KBPSD →200 KBPSD ) for FCC Unit of Reliance Jamnager Refinery | SA387-22-1 | Modification planning | 2004-10 2005-09 |

| 26 | India | Reliance | Revamping (Up grading 30 KBPSD → 40 KBPSD ) for Vacuum Distillation Unit of Reliance Jamnager Refinery | A387, Gr.5, SA516-70+SA240-410S | Design, Fabrication & Modification for Equipment, Piping, Structure & Others | 2003-09 2004-12 |